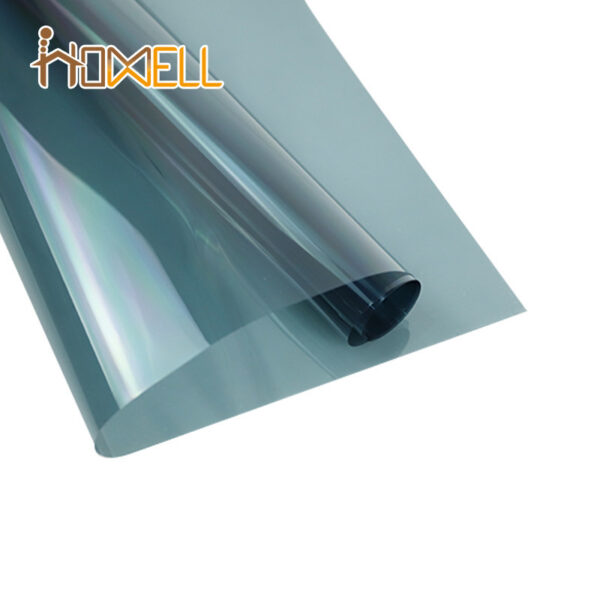

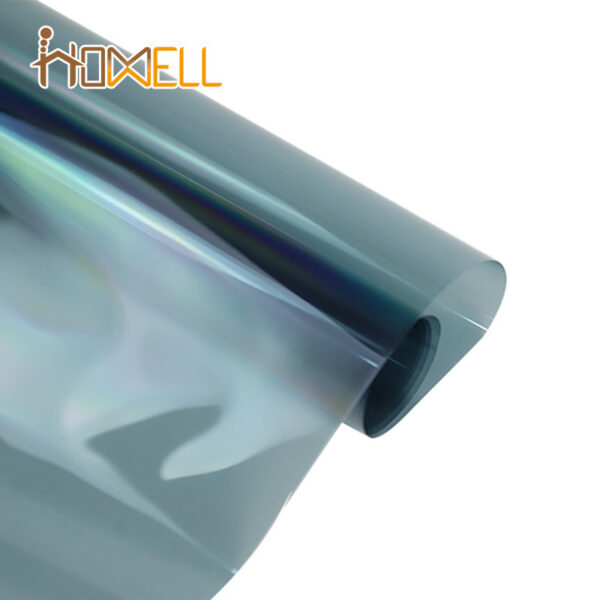

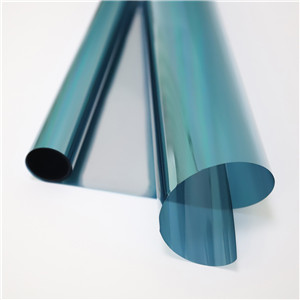

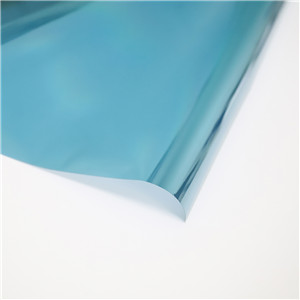

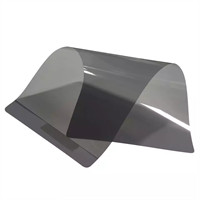

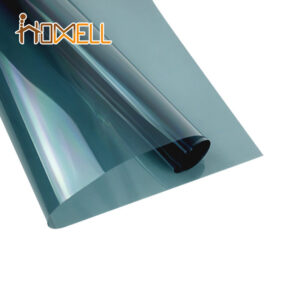

Heat insulation film-1

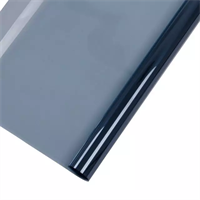

Technical Performance Parameters:

Visible Light Transmittance (VL%): 78-83%;

Infrared Transmission (IR%): 20±2%;

Ultraviolet Transmittance (UV%): <1%;

Solar Energy Rejection: 53-57%;

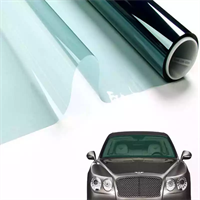

Shading Coefficient (SC): 0.6. The product is applicable to high-end buildings such as airports, luxury villas, and golf venues, with the standards of high transparency, high insulation, and low sensitivity on price. Product specification:

Comment: Specific width and length are provided according to the requirements of clients.

- Description

- Inquiry

ADVANTAGES:

★ High heat insulation while ensuring high light transmission

By nano character of the new material,80% visible light from sunlight come indoor to guarantee natural light needed.

★ Heat insulation

Our new material can barrier 90% infrared which deduce air condition load and lower refrigeration consumption. Meanwhile,it also block Infrared heat energy at high rate from air and ground where air conditioning load mainly generate at cloudy day and night.Regular sunshade methods not possess this function.

★ Maintain temperature

Holding infrared heat energy inside in winter to the purpose that keep indoor warm and reduce heating cost.

★ Anti-UV

Blocks up to 99% of UV rays, avoiding UV harm to human skin and furniture,flooring and curtain color fading.

★ No signal shielding, no light pollution

The energy-saving film is based on nano material. It selectively transmits and absorbs light of various wavelengths in sunlight. There is no metal coating of traditional heat insulation film, so there is no light pollution. No shielding of wireless signals

★ Dry glue system

The mounting glue is made of polyester, which has a large molecular weight, good weather resistance, easy drying, minimal residual solvent, and high cost. Dry glue does not generate bubbles when heated, tearing the protective film is odorless, non-sticky, easy to apply

★ Anti-explosion

Deduce possibility of glass broken to pieces from high above the ground. To aviod human injured by accident in maximum.

Working principle

The energy-saving film is made of nano metal oxide. The nano-effect of this material makes the visible light band transmittance of sunlight reach 80%, and it blocks ultraviolet rays more than 99%. At the same time, it selectively absorbs the total energy of sunlight and secondary radiation to make the mid-near infrared blocking rate exceeds 90%. Under the premise that the film has limited influence on indoor lighting, it can block the heat of the mid-near infrared rays into the room to the greatest extent, thereby greatly improving the efficiency of air conditioning.

In summer: the heat of ordinary glass entering the room is Q = 643.9w /㎡/ h, and the glass after filming is calculated according to (Sc average 0.42). The heat entering the room is Q = 313.6w /㎡/ h, then it can be calculated: Film-coated glass can reduce the heat of 330.3w / w /㎡/ h into the room, the energy saving ratio is 51%.

In winter, according to the indoor and outdoor temperature difference of 20℃, the heat lost by ordinary glass is Q = 116w / w /㎡/ h, and the heat lost by glass after film is Q = 98w /㎡/ h, can reduce the heat loss of 18w /㎡/ h, the energy saving ratio is 15.5%.

Therefore, after a maximum of one year, you can recover the cost of purchasing energy-saving films, and can continue to enjoy the benefits brought by energy-saving films for at least 10 years.